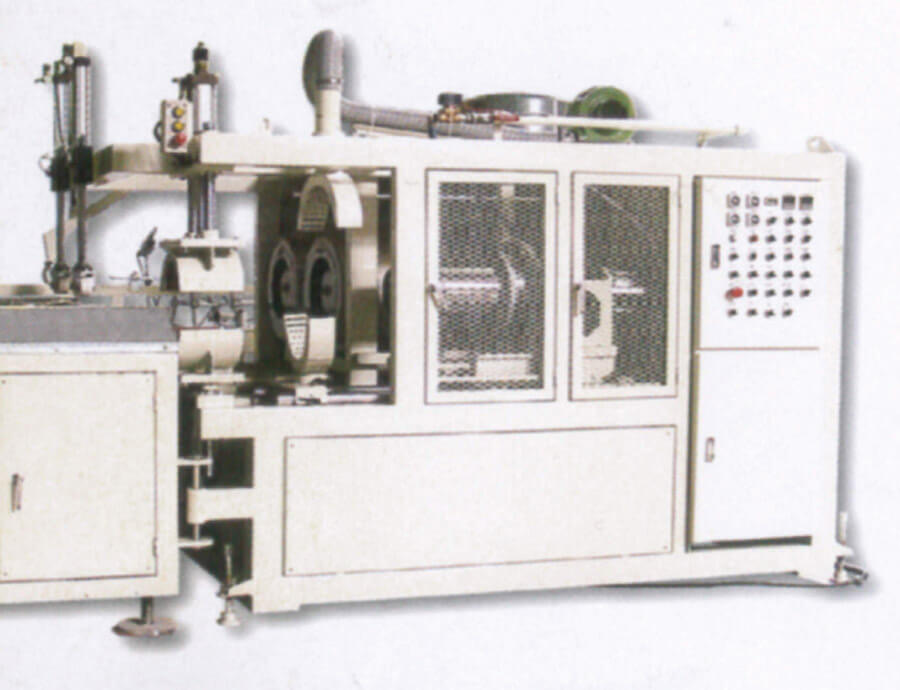

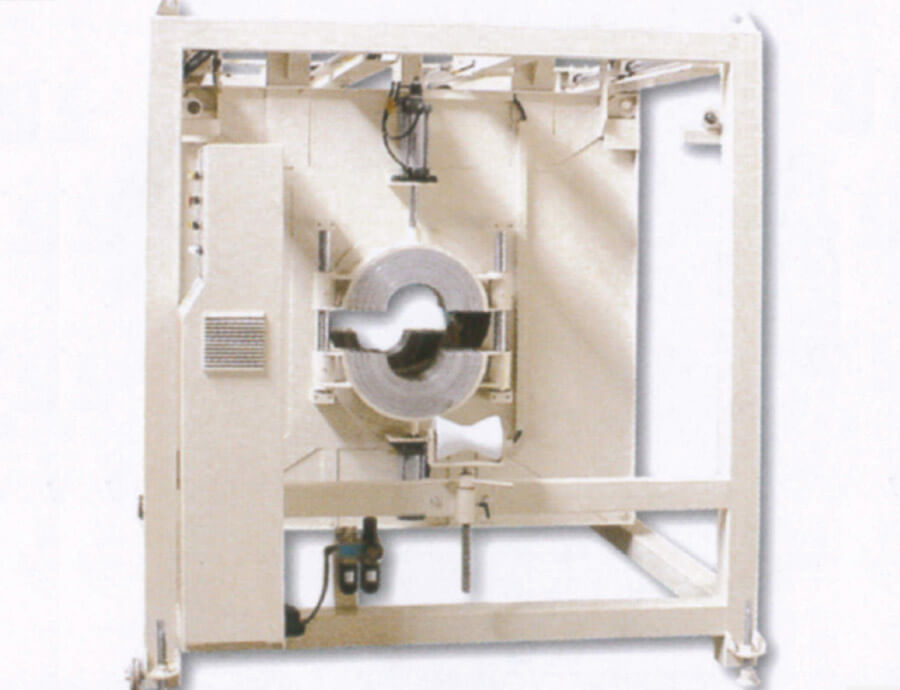

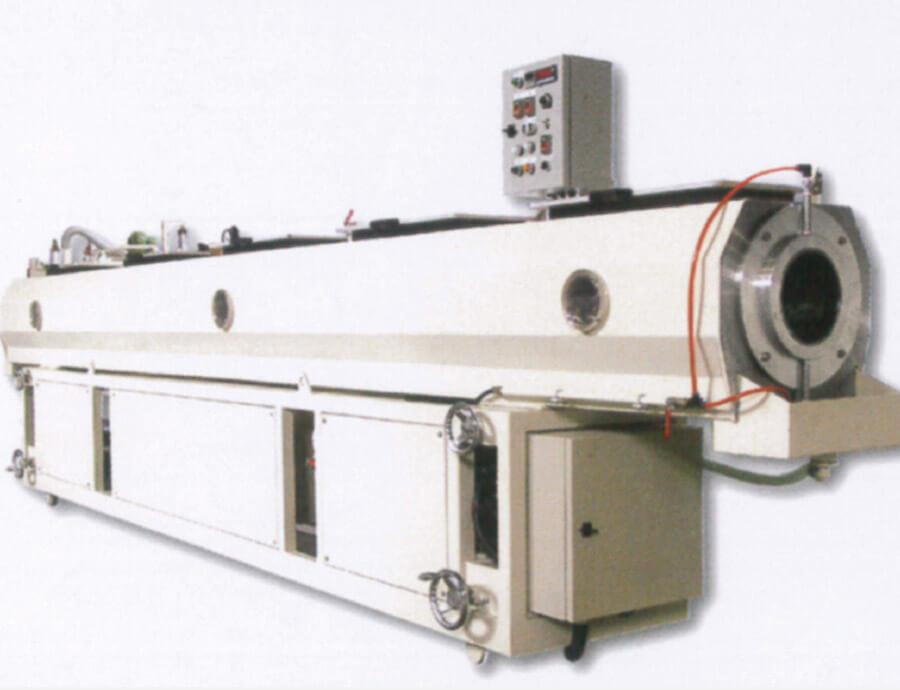

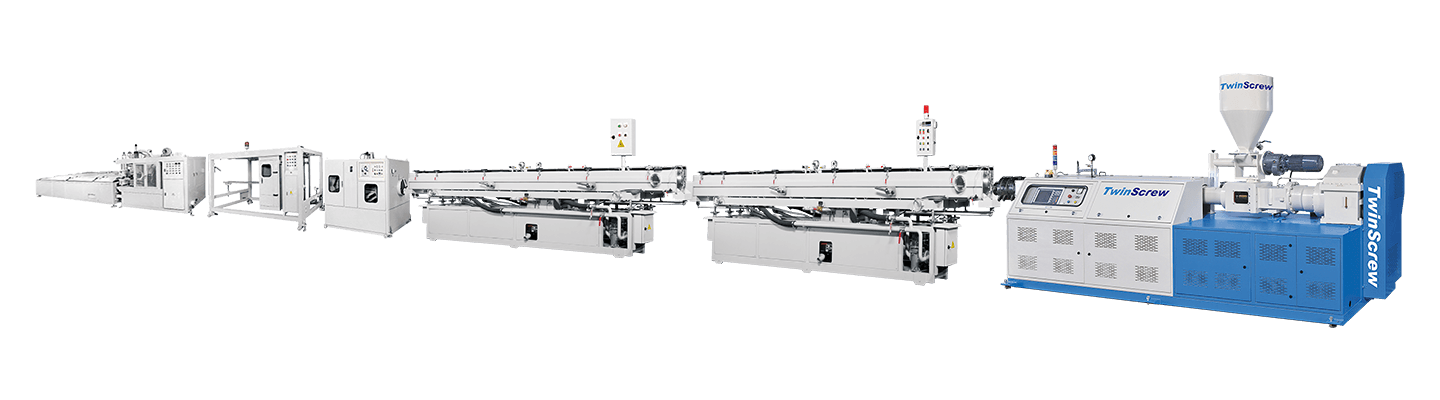

Twin Screw PVC Single Line Rigid Pipe Making Machine

Applications

Description

Related Video

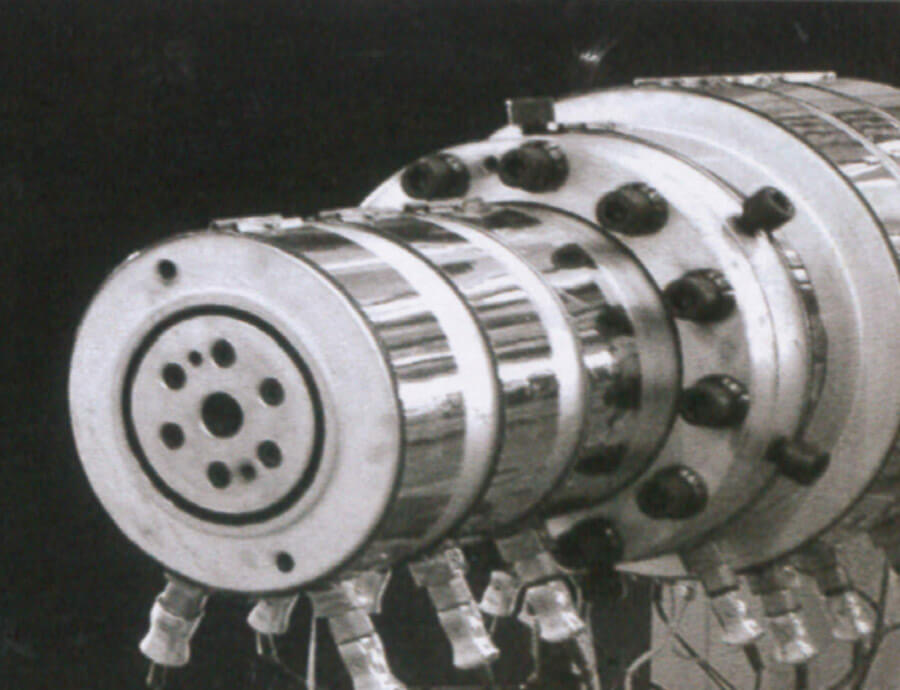

The concept of the spider die guarantees outstanding product characteristic for PVC material.

The benefits:

Ideal residence time profile over the whole flow cross-section

Homogeneous melt distribution

Simple and reliable handling